| Insulated Thermocouples | |

| Fluororesin Insulated Thermocouples | |

| Fluororesin Insulated extreme thin thermocouple Fineflex ® |

Insulated thermocouples are duplex thermocouples that are useful with excellent flexibility and with simple anatomy. Insulated thermocouples are double covered insulation on thermocouple bare wire guaranteed for accuracy of measurement.

We will immediately deliver orders for insulated thermocouples as we always keep them in stock.

Please appoint the processing method of insulated thermocouples for the whole length or for terminal parts at the time of ordering welding the contact points of temperature measurement.

The classifications of insulated thermocouples are as follows:

(1) Vinyl insulated thermocouples

(2) Glass insulated thermocouples

(3) Fluorine resin insulated thermocouples

(4) Super heat-resistant insulated thermocouples

The features of insulated thermocouples are

The features of insulated thermocouples are

- The prices are low.

- Easy to process at the point of contact for temperature measurement.

- Excellent flexibility.

- Possible to maximize the length with the process on the spot.

- 5. T insulated thermocouples use highly accurate insulated thermocouple bare wire, from 0 ~100˚C +_0.5˚C and from 0 ~ 218˚C +_ 0.87˚C, and it is possible to measure temperature with high accuracy under 200˚C.

The classifications of insulated thermocouples and conductor standards

The classifications of insulated thermocouples and conductor standards

| The classifications | Insulated type | Insulator type | Core wire materials | Linear diameter (mm) |

Heat electromotive force(mV) Standard point of contacting 0˚C | |||

|---|---|---|---|---|---|---|---|---|

| + side core | - side core | + side core | - side core | 100˚C | 218˚C | |||

| K | Blue | Red | White | Chronic*1 | Alunic*1 | 1/0.32 1/0.65 |

4.096±0.062 (±1.5˚C) |

8.860±0.060 (±1.5˚C) |

| E | Purple | Red | White | Chronic*1 | Copper-Nickel Alloy | 6.319±0.100 (±1.5˚C) |

14.762±0.110 (±1.5˚C) | |

| J | Yellow | Red | White | Iron | Copper-Nickel Alloy | 5.269±0.080 (±1.5˚C) |

11.778±0.080 (±1.5˚C) | |

| T | Brown | Red | White | Copper | Copper-Nickel Alloy | 4.279±0.023 (±0.5˚C) |

10.254±0.047 (±0.87˚C) | |

*1 Chronic and Alnich are our registration trademarks of Chromel and Almel.

We will introduce the classifications of insulated thermocouples and their features. Please choose with your order.

| K insulated thermocouples | The temperature ranges used are most diverse from -200˚C ~ 1200˚C, and also most similar to a straight line as in the relationships of temperatures in-between them and heat electromotive force. K insulated thermocouples are inexpensive on a comparison with noble metal thermocouples, and so they are most diversely used as industrial thermocouples. |

|---|---|

| E insulated thermocouples | These have the highest heat electromotive force among thermocouples used today, and they are the most sensible thermocouple. E insulated thermocouples are 50% higher on a comparison with K insulated thermocouples and are 20% higher on a comparison with J insulated thermocouples in heat electromotive force. Therefore, they are used within a temperature range below 700˚C to 800˚C. |

| J insulated thermocouples | These are usually used for temperature measurement under 600˚C. They have the second best sensibility next to E insulated thermocouples, and on a comparison with E insulated thermocouples, they are more inexpensive in value. Furthermore, J insulated thermocouples have strength sufficient for use at reduced atmosphere. |

| T insulated thermocouples | These are usually used for temperature measurement under 300˚C. Since they have high accuracy and the excellent process ability for drawing, they are widely used as highly accurate insulated thermocouples for low temperature, and are processed on glass fiber or Fluororesin insulation. These thermocouples are also widely used as insulated thermocouples for extremely low temperature. |

* Our standard insulated thermocouple products are different from the ones for usual temperatures listed above due to thin wire diameters of 0.32 and 0.65 (refer to graph-1).

|

Standard insulated thermocouple products

Standard insulated thermocouple products

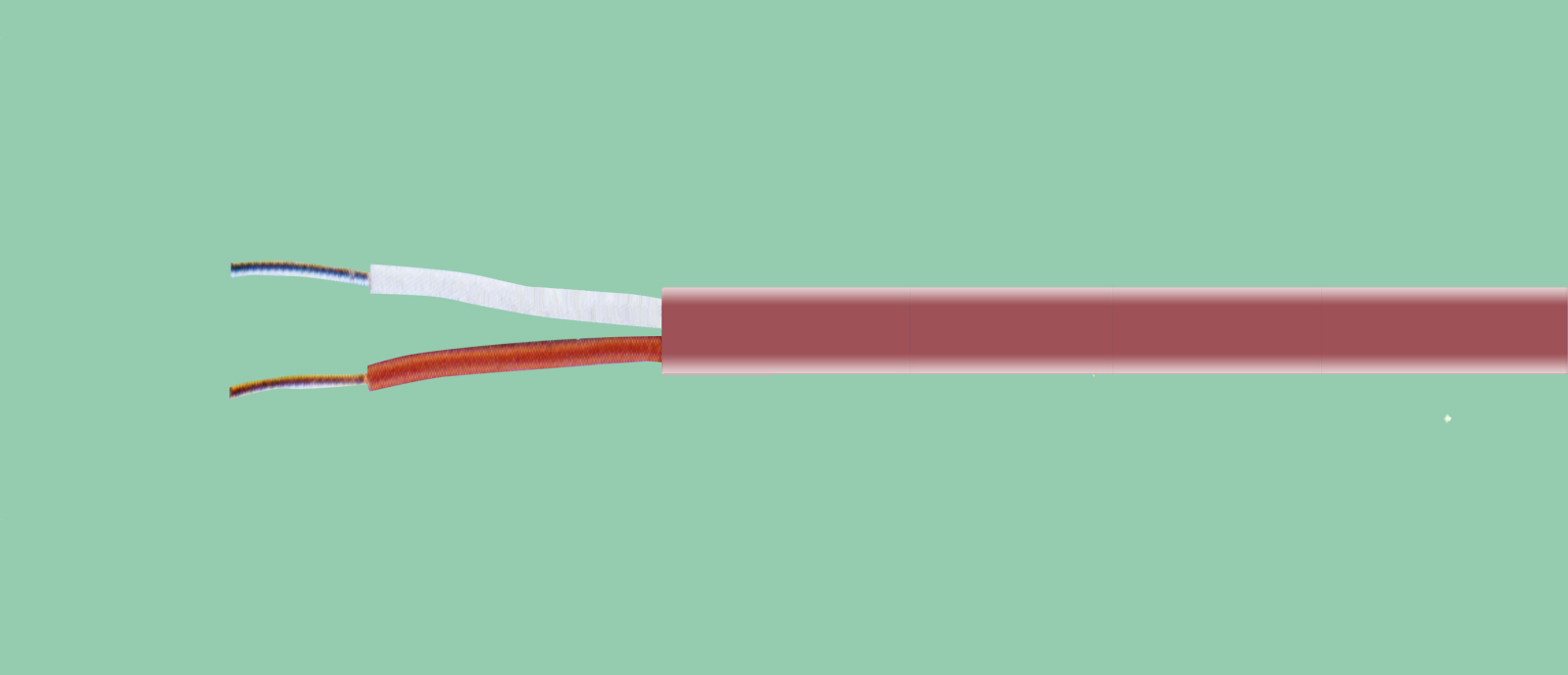

1. The classifications and lengths of insulated thermocouples

| No. | Classifications | Standard products | Formal symbols | Wire diameter | Standard matching length | Insulation, Protection insulation | |

|---|---|---|---|---|---|---|---|

| mm | mm | Materials | Highest temperature used for insulation (˚C) | ||||

| 1 | K |  |

K-0.75=VVF | 1/0.32 1/0.65 |

2.2×3.4 2.5×4.0 |

Vinyl | 60 |

| 2 | E | E-0.75=VVF | |||||

| 3 | J | J-0.75=VVF | |||||

| 4 | T | T-0.75=VVF | |||||

| 5 | K |  |

K-0.75=GGF | 1/0.32 1/0.65 |

1.7×2.5 2.2×3.3 |

Glass fiber braid | 150 |

| 6 | E | E-0.75=GGF | |||||

| 7 | J | J-0.75=GGF | |||||

| 8 | T | T-0.75=GGF | |||||

| 9 | K |  |

K-0.4=FEPFEPF | 1/0.32 1/0.65 |

1.0×1.6 1.5×2.4 |

Fluorine resin | 200 |

| 10 | E | E-0.4=FEPFEPF | |||||

| 11 | J | J-0.4=FEPFEPF | |||||

| 12 | T | T-0.4=FEPFEPF | |||||

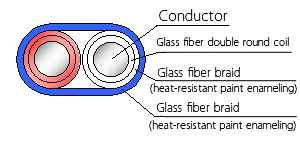

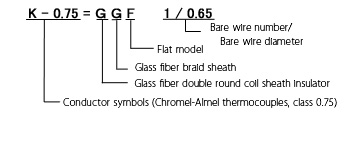

(1) Glass Insulated thermocouples Explanation of each symbol

Explanation of each symbol

|

|